Stainless steel mesh slitting

We specialize in the precision processing and diverse surface treatments for stainless steel mesh. We are committed to providing customers with high-performance, reliable product solutions. Our core services include:

Oil, dust, and impurities are effectively removed from the surface of metal wires or their components via ultrasonic cleaning, water washing, or thermal cleaning, ensuring the product cleanliness meets required standards.

The calendering process is used to flatten metal wires and reduce their thickness, ensuring a uniform and precise overall mesh thickness – ideal for applications with strict thickness control requirements. In addition, calendering enhances the structural stability of woven stainless steel mesh.

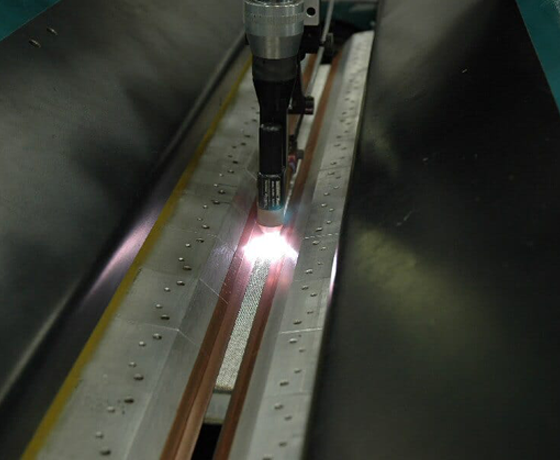

Equipped with advanced laser cutting systems, we deliver high-precision cutting suitable for complex shapes and tight tolerance requirements in filter components and metal mesh part fabrication.

Stainless steel mesh slitting

Stainless steel mesh calendering

Stainless steel mesh welding

Stainless steel mesh laser cutting