Spacing and precision measurement

904L stainless steel wire mesh, precision-woven from low-carbon, high-nickel, and high-molybdenum austenitic stainless steel, demonstrates excellent performance in inorganic acids, organic acids, and chloride-containing environments due to its elevated nickel and molybdenum content, exhibiting exceptional resistance to pitting corrosion, crevice corrosion, and stress corrosion cracking. The addition of copper further enhances its corrosion resistance in sulfuric acid across all concentrations, while also delivering superior stability in non-oxidizing acids such as acetic, formic, and phosphoric acids. The low-carbon design effectively improves intergranular corrosion resistance and provides enhanced oxidation resistance at elevated temperatures. It is suitable for corrosive environments involving various concentrations of sulfuric acid below 70 °C and acetic acid at any concentration under ambient pressure.

Chemical Composition

| Chemical Composition | C | N | Mo | Si | Cu | Mn | P | W | S | Cr | Ni |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Content | 0.017 | - | 4.22 | 0.33 | 1.16 | 1.53 | 0.026 | - | 0.03 | 19.09 | 26.51 |

Mechanical Properties

| Mechanical Properties | Tensile Strength (kg/mm2) | Yield Strength | Elongation (%) | Heat Treatment Condition |

|---|---|---|---|---|

| Index | 620 | 450 | 25 | Bright annealing |

Weaving Method

Features

Applications

Gallery

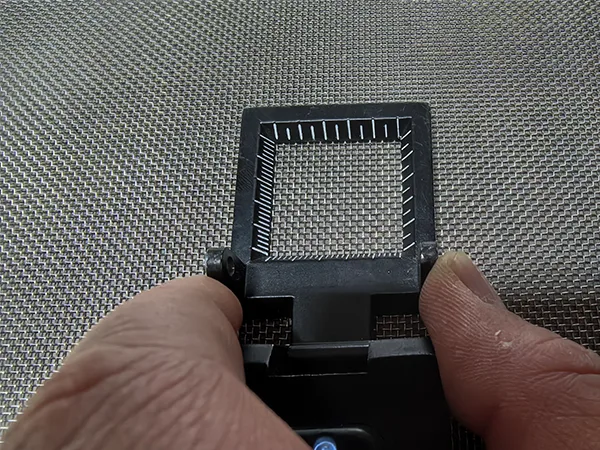

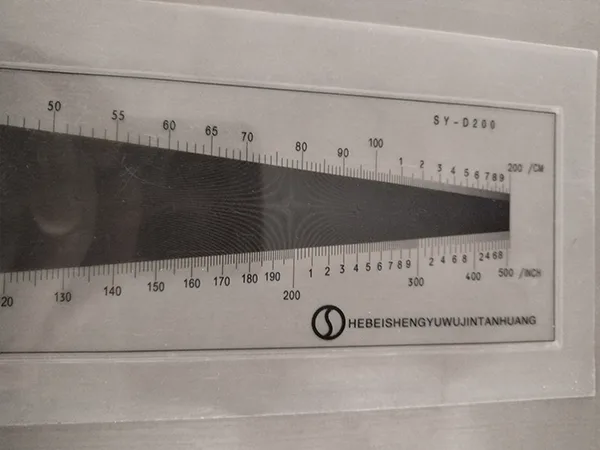

Spacing and precision measurement

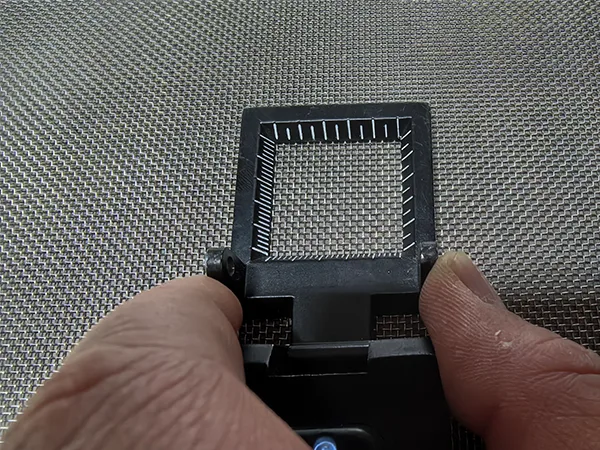

Mesh count inspection

Wire diameter measurement