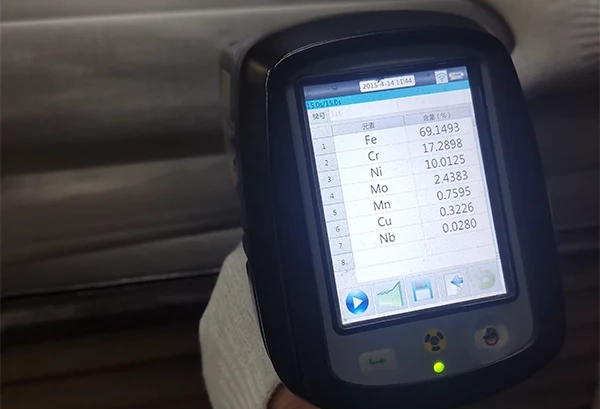

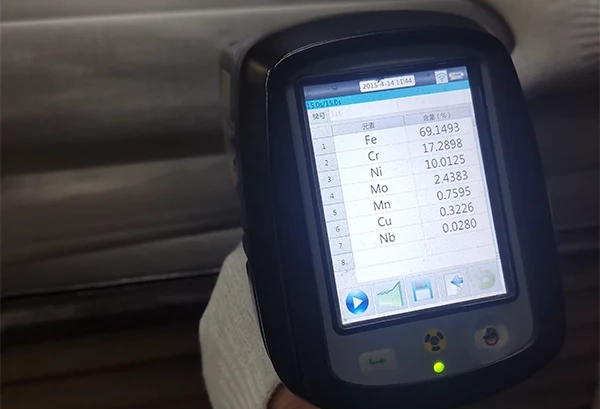

Material testing

316 stainless steel woven mesh is a high-strength mesh material made from precision-woven 316 stainless steel wire. It is widely used in chemical, petroleum, marine, and highly corrosive environments. Due to the excellent corrosion resistance and oxidation resistance of 316 stainless steel, it can withstand relatively harsh working conditions, particularly performing well in chlorine-containing or at high temperature environments.

316L stainless steel woven mesh, made from low carbon 316L stainless steel wire, is specifically designed for applications requiring outstanding corrosion resistance and weldability. Compared to 316 stainless steel, 316L has a lower carbon content, making it less prone to intergranular corrosion during high-temperature and welding processes, while maintaining excellent strength and corrosion resistance after welding.

Comparison

| Characteristics | 316 Stainless Steel Woven Mesh | 316L Stainless Steel Woven Mesh |

|---|---|---|

| Chemical composition | Contains 0.08% of carbon | Contains 0.03% of carbon or lower |

| Corrosion resistance | Excellent corrosion resistance, suitable for various harsh environments | Superior corrosion resistance, especially suitable for strong acids, chlorides, and other environments |

| Oxidation resistance | Good oxidation resistance | Stronger oxidation resistance, suitable for high-temperature applications |

| Welding performance | Weldability is good, but inferior compared to 316L | Superior welding performance, and the strength is not easy to decrease after welding |

| Strength | Strength slightly higher than 316L | Strength slightly lower than 316, but sufficient for many applications |

| Applications | It is often used where it is necessary to enhance the resistance to chloride ion corrosion, such as oil, natural gas, seawater desalination equipment, pulp and paper and other fields | It is often used in environments requiring high weldability and low carbon content, such as pharmaceuticals, food processing, offshore platform components, etc |

| Stress corrosion cracking resistance | Good stress, corrosion and cracking resistance | Superior stress, corrosion and cracking resistance |

Chemical Composition

| Grade | Content | C | Si | Mn | P | S | Cr | Ni | Mo |

|---|---|---|---|---|---|---|---|---|---|

| SUS316 | Min. | – | – | – | – | – | 16 | 10.0 | 2 |

| Max. | 0.08 | 0.75 | 2.0 | 0.045 | 0.03 | 18 | 14.0 | 3 | |

| SUS316L | Min. | – | – | – | – | – | 16 | 10.0 | 2 |

| Max. | 0.03 | 1.00 | 2.0 | 0.045 | 0.03 | 18 | 14.0 | 3 |

Weaving Method

Gallery

Material testing

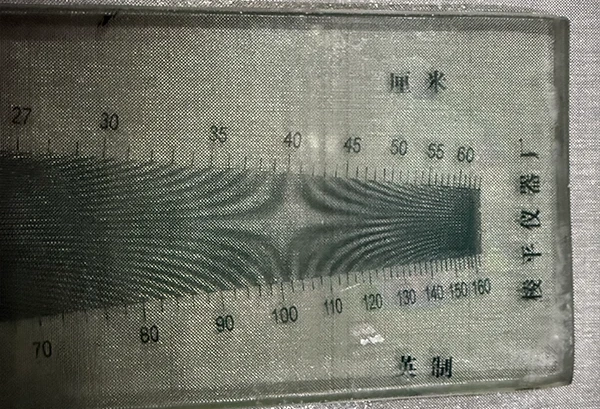

Mesh count testing

Length measurement

Length measuring instrument

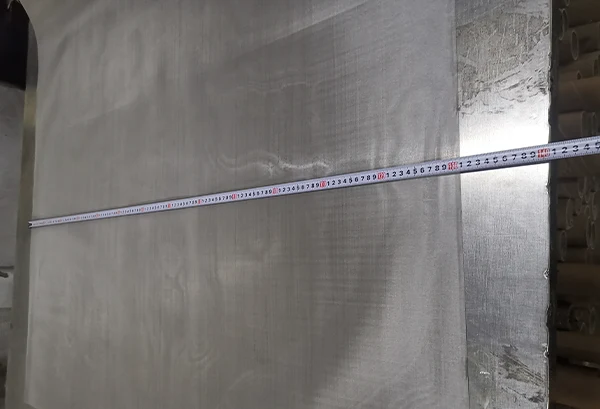

Width measurement

Wooden box packaging