Wind tunnel screen, also known as damping net, is a kind of metal woven mesh used in wind tunnel laboratories. A wind tunnel laboratory can be deemed as a kind of tunnel that generates artificial air flow to study the aerodynamic effects of air flow when passing through objects. It is widely used in the design of cars, aircraft, missiles, high-speed trains, ships, and buildings.

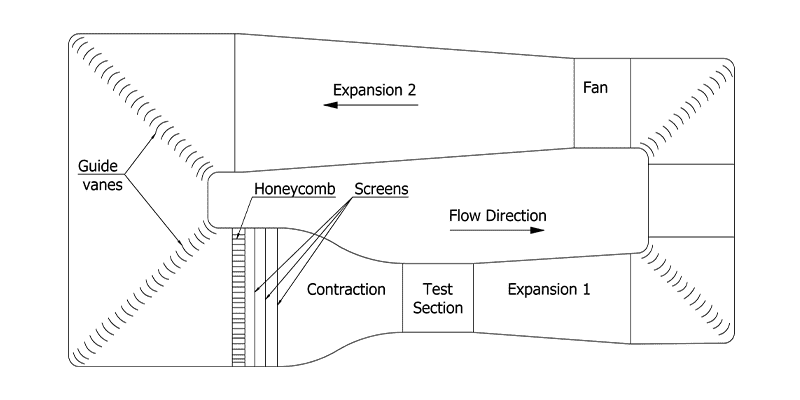

In wind tunnel laboratories, a powerful fan device or a system with similar effect is usually used to generate air flow. In this process, rotary air flows are produced. To make the test results more precise, the airflow state during the experiment must be kept similar to the actual airflow state. So, wind tunnel screen plays an important role in stabilizing the airflow.

Working Principle

Wind tunnel screens are placed in front of a fan device and can be arranged in multiple layers from coarse mesh to fine mesh to diffuse the rotating airflow caused by the fan and to distribute the airflow evenly. We can produce up to 25 m width wind tunnel screens with highly air permeability, rigidity and vibration resistant. What's the most important is that it is a mesh screen without any welding or splicing to ensure the airflow is evenly distributed over the entire surface.

Specifications

Made-to-Order Service

Boegger offers all links of services required from wind tunnel screen production to installation. We believe that working with customers is the best way to develop the right wind tunnel screens. We can discuss your air permeability, aperture, wire diameter and material requirements together to find the right product perfect for you..