321 stainless steel wire mesh

321 stainless steel wire mesh is woven from high-quality 321 stainless steel wires, offering excellent oxidation resistance and intergranular corrosion resistance, making it suitable for filtration, screening, and protection in high-temperature environments. Its titanium content enhances high-temperature performance, maintaining stability within the range of 900-1600 °F. 321 stainless steel wire mesh is widely used in fields of petrochemicals, aerospace, food processing, pharmaceuticals, and machinery manufacturing. It comes in various mesh sizes, wire diameters, weaving methods, and dimensions to meet diverse application needs.

Chemical Composition

| Chemical Composition | C | Si | Mn | S | P | Cr | Ni | Ti |

|---|---|---|---|---|---|---|---|---|

| Content | ≤ 0.08 | ≤ 1.00 | ≤ 2.00 | ≤ 0.030 | ≤ 0.045 | 17.00–19.00 | 9.00–12.00 | ≥ 5 × C |

Mechanical Properties

| Mechanical Properties | Tensile Strength σb (MPa) |

Conditional Yield Strength σ0.2 (MPa) |

Elongation δ5 (%) |

Reduction of Area Ψ (%) |

Hardness |

|---|---|---|---|---|---|

| Index | ≥ 520 | ≥ 205 | ≥ 40 | ≥ 50 | ≤ 187 HB ≤ 90 HRB ≤ 200 HV |

Weaving Method

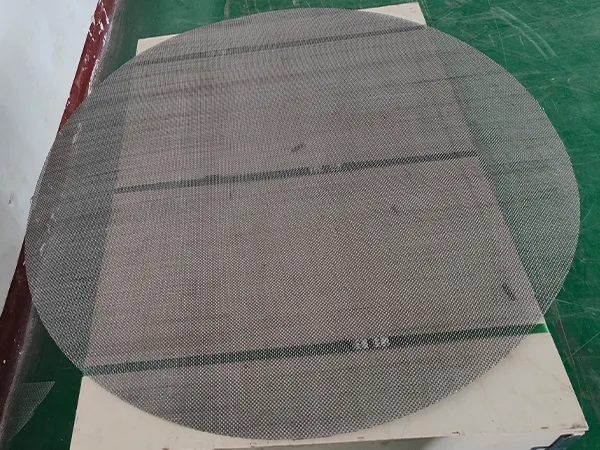

Gallery

321 stainless steel wire mesh

Plain weave

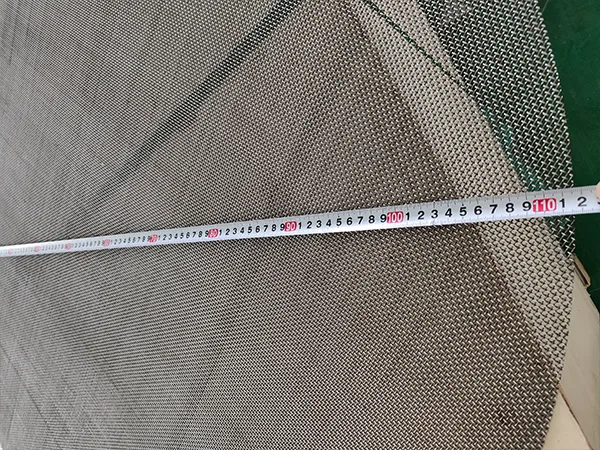

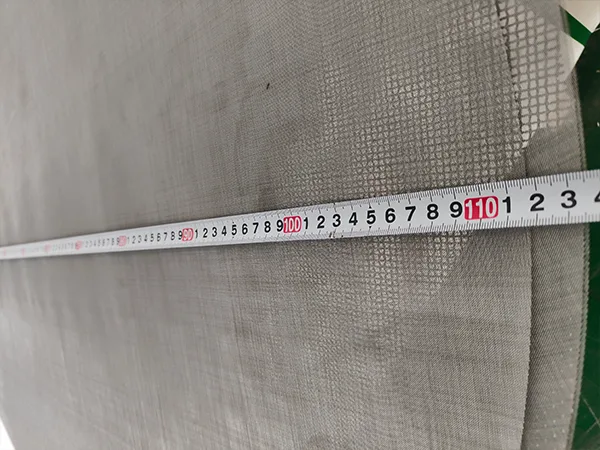

Measure diameter