Reverse dutch woven style

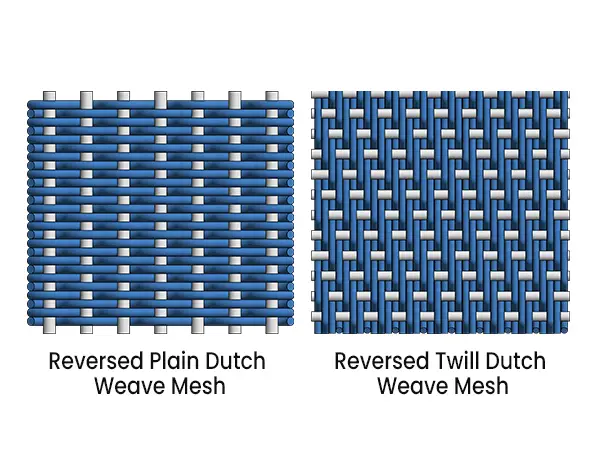

Reverse dutch wire cloth is a high-performance filter mesh made of stainless steel, categorized into reversed plain dutch weave mesh and reversed twill dutch weave mesh based on the weaving method. Reverse plain dutch weave mesh is commonly used as a filter element in vertical leaf filters, horizontal filter presses, centrifuges, and backwashable drum filters. Twill Dutch weave mesh is suitable for high-pressure filtration and is often used as a continuous screen in polymer filtration.

The apparent difference of Reverse Dutch Weaving compared with standard Dutch weave lies in the thicker warp wires and less weft wires. Reverse Dutch woven stainless steel wire cloth offers finer filtration and finds popular application in petroleum, chemical, food, pharmacy and other fields.

Through constant technological innovation and improvement, we can produce stainless steel wire mesh of various specification in reverse Dutch weaving patterns.

Reverse dutch woven style

Stainless steel reverse dutch woven wire cloth

Reverse dutch stainless steel woven cloth roll

Reverse dutch SS woven cloth rolls

| Model | Mesh Count (Warp × Weft) | Warp Wire Diameter | Weft Wire Diameter | Porosity | Thickness | Weight | Filter Rating | |||

|---|---|---|---|---|---|---|---|---|---|---|

| – | Inch | Inch | mm | Inch | mm | % | Inch | mm | kg/m2 | μm |

| RPDW-66200 | 66 × 18 | 0.012 | 0.3 | 0.016 | 0.40 | 66 | 0.042 | 1.07 | 2.22 | 200 |

| RPDW-49150 | 84 × 25 | 0.013 | 0.32 | 0.016 | 0.40 | 49 | 0.043 | 1.09 | 3.09 | 150 |

| RPDW-53100 | 130 × 30 | 0.008 | 0.20 | 0.018 | 0.45 | 53 | 0.032 | 0.82 | 2.82 | 100 |

| RPDW-56080 | 130 × 35 | 0.008 | 0.20 | 0.016 | 0.40 | 56 | 0.030 | 0.75 | 2.70 | 80 |

| RPDW-58104 | 175 × 40 | 0.006 | 0.15 | 0.014 | 0.35 | 58 | 0.022 | 0.55 | 2.24 | 104 |

| RPDW-56100 | 175 × 45 | 0.006 | 0.15 | 0.013 | 0.32 | 56 | 0.024 | 0.62 | 2.16 | 100 |

| RPDW-53060 | 175 × 50 | 0.006 | 0.15 | 0.012 | 0.30 | 53 | 0.022 | 0.56 | 2.14 | 60 |

| RPDW-50050 | 290 × 60 | 0.004 | 0.09 | 0.009 | 0.23 | 50 | 0.016 | 0.40 | 1.36 | 50 |

| RPDW-52040 | 290 × 74 | 0.004 | 0.09 | 0.008 | 0.20 | 52 | 0.014 | 0.36 | 1.27 | 40 |

| Model | Mesh Count (Warp × Weft) | Warp Wire Diameter | Weft Wire Diameter | Porosity | Thickness | Weight | Filter Rating | |||

|---|---|---|---|---|---|---|---|---|---|---|

| – | Inch | Inch | mm | Inch | mm | % | Inch | mm | kg/m2 | μm |

| RTDW-58400 | 72 × 15 | 0.018 | 0.450 | 0.018 | 0.450 | 58 | 0.069 | 1.75 | 4.43 | 400 |

| RTDW-45350 | 132 × 16 | 0.014 | 0.022 | 0.022 | 0.560 | 45 | 0.049 | 1.25 | 5.40 | 350 |

| RTDW-58250 | 132 × 16 | 0.014 | 0.352 | 0.018 | 0.457 | 58 | 0.049 | 1.24 | 4.90 | 250 |

| RTDW-57200 | 132 × 18 | 0.014 | 0.355 | 0.018 | 0.455 | 57 | 0.052 | 1.31 | 4.65 | 200 |

| RTDW-42165 | 152 × 24 | 0.012 | 0.315 | 0.014 | 0.355 | 42 | 0.047 | 1.20 | 4.53 | 165 |

| RTDW-42150 | 160 × 24 | 0.012 | 0.305 | 0.016 | 0.400 | 42 | 0.043 | 1.09 | 4.68 | 150 |

| RTDW-39145 | 160 × 25 | 0.012 | 0.315 | 0.016 | 0.400 | 39 | 0.043 | 1.10 | 4.97 | 145 |

| RTDW-47100 | 228 × 36 | 0.007 | 0.190 | 0.011 | 0.280 | 47 | 0.026 | 0.67 | 2.71 | 100 |

| RTDW-53125 | 260 × 40 | 0.006 | 0.150 | 0.009 | 0.220 | 53 | 0.024 | 0.62 | 1.98 | 125 |

| RTDW-43055 | 325 × 39 | 0.006 | 0.150 | 0.012 | 0.300 | 43 | 0.028 | 0.70 | 2.71 | 55 |

| RTDW-61060 | 400 × 120 | 0.003 | 0.065 | 0.004 | 0.100 | 61 | 0.010 | 0.26 | 0.72 | 60 |